Innovativ

Projekte

Färber

Energy Concepts

We build the future – with energy!

The management of Innovativ-Projekte-Färber GmbH & Co. KG works out answers for energy problems or even an energy crisis and offers you sustainable solutions.

Energy concepts with hydrogen

Today the hydrogen production is either grey, blue or green:

- Gray means hydrogen production is mainly by steam reforming (without CCS) or as a by-product.

- Blue means hydrogen production is by natural gas reforming with CCUS (SMR, ATR, POX; blue hydrogen)

- However, green is the long-term goal and means obtaining the hydrogen from electrolysis, for example, and providing the necessary electricity using renewable energies.

Hydrogen instead of natural gas

Hydrogen instead of natural gas

The demand for natural gas will decrease by 2050, not least due to the Ukraine conflict, and will be replaced by hydrogen in several applications.

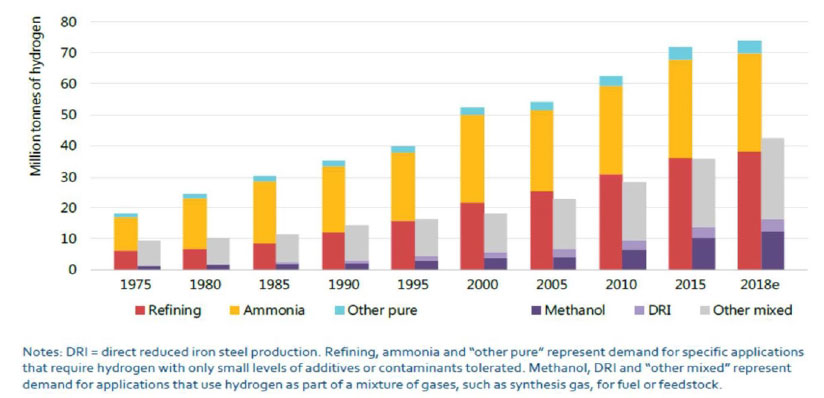

The IEA analysis shows that the global hydrogen demand is more than 70 million tons (2750 TWh), mainly in refining and ammonia production.

Green hydrogen – with us today

We advise on solutions with hydrogen in connection with wind, solar or hydropower.

Mobile, modular and inexpensive.

Talk to us.

Current alternative I

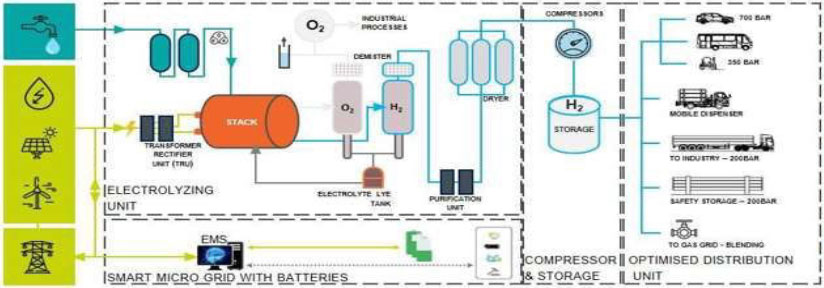

Electrolysis

With this alternative, the electricity for the electrolysis required for hydrogen production comes from a private operated waste-to-energy plant. The associated hydrogen filling station is also planned there, which vehicles, including garbage trucks, are to use as a drive in the future.

We are already well advanced in the development of such a project with a partner.

Current alternative II

Synergy

Another project development is underway on the basis of the German national H2 strategies.

The key of the project is to work with a country with a high number of sunny days and to develop a large-scale green hydrogen production facility. The project covers an area of 6000 m² and consumes a maximum of 32 MW peak power. Other auxiliary facilities cover an area of another 2,000 m².

The produced green hydrogen is brought back to Germany to meet the demand for green energy in the German market. The systems are located in 40″ containers and are also mobile.

Applications with hydrogen

Applications with hydrogen as an energy carrier for an energy supply that is climate-neutral and CO2-neutral and does not require oil or gas:

- Chemical industry, for example for conversion into ammonia

- Generation of heat, cold and electricity

- Substitute for district heating to supply residential areas

However, it will take a long time before the infrastructure in Germany has been converted to this technology. In addition, so far only very few energy production plants can process hydrogen. After all, in natural gas networks, the admixture of hydrogen is only possible up to a maximum of 10%.

Our interim solution I

Biogas

Biogas as the basis for power generation

We advise on the planning and construction of fermentation plants / biomass fermentation plants and also implement them as a general contractor.

In these plants, biomass is not just simply composted, but other utilization options are exploited. The biomass, mainly waste from the compost bin, is decomposed by microorganisms in closed fermenters in the absence of oxygen, under pressure and sprinkled with process water. This produces methane, which is collected and fed to a power generation plant.

The resulting electricity is fed into the power grid and the resulting heat is used to heat (municipal) facilities and buildings. The remaining fermentation residues are mixed after the process is complete and can be used, for example, as potting soil.

Our interim solution I

Synthetic methane gas

Synthetic methane gas by converting CO2

However, the CO2, which is considered harmful all over the world, can be used as a raw material and converted into methane gas, which can be used in the existing applications in exchange for natural gas.

But where is the easiest place to get the CO2 from?

In the biological fermentation arise, 50% CH4 and 50% CO2. This means that the productivity of a biomass digestion plant can be increased by approximately 100%, and the additional synthetic methane gas can be used to replace natural gas in current applications. CO2 + 4 H2 becomes CH4 + 2 H2O, so this conversion also requires hydrogen.

Together with international scientists, we have now developed a technology that, in addition to thermal cracking, which is not wanted because it is very energy-intensive, also transforms the CO2. The CO2 generated in the combustion process is then recirculated. Of course, the CO2 can also be supplied from storage facilities (CCS).